1. Environment-friendly and low noise design.

2. Equipped with auto-locking plate style carriage, with high strength and strong engagement of the locking teeth and lifting arms.

3. The back of the carriage is welded with a lifting bar, which is locked with the locking hook of the main and secondary column, making it safer and more reliable. The unlocking was controlled by the stacked telescopic locking bar. While complying with the minimum safety position of the equipment, it ensures that the locking bars run aesthetically and do not extend out of the column.

4. Auto-handle control single-point safety release. The lifting and lowering was operated with only one handle, with simple and convenient operation.

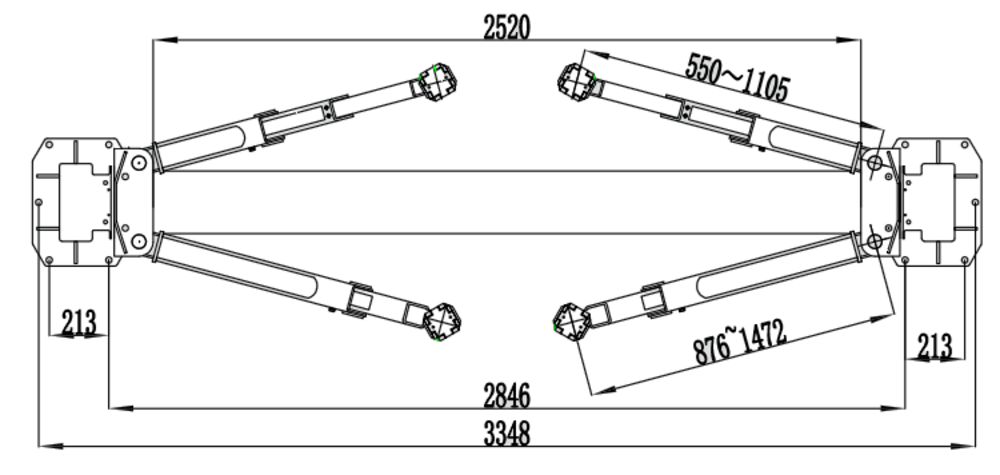

5. Symmetric arm design, optional 2+3-stage or 3+3-stage lifting arms, which can meet more maintenance needs.

6. Equipped with a power unit with low power consumption, high efficiency, less failure and low noise.

7. Equipped with an oil-immersed motor. The motor and oil pump work in hydraulic oil, which prolongs the working life of the motor and oil pump.

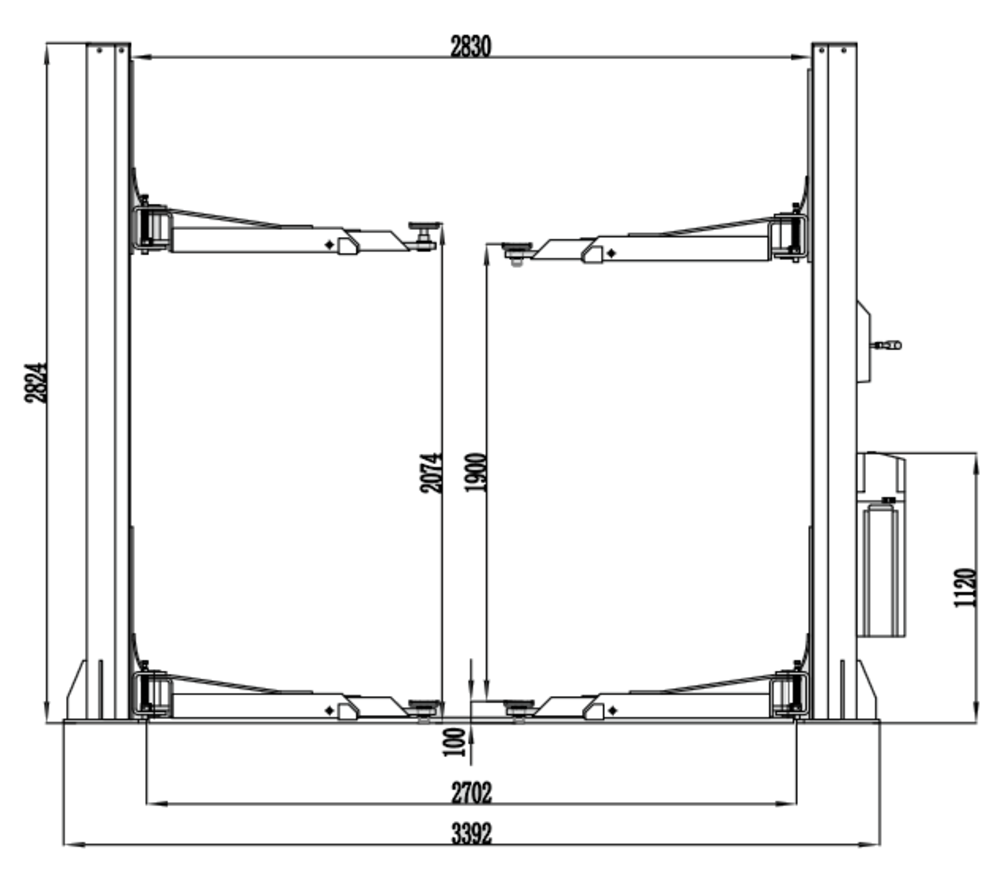

| Technical Parameters | | | Lifting height | | 100-2074mm | | Overall height | | 2824mm | | Overall width | | 3392mm | Drive-thru width

| | 2520mm | Arm size (3)

| | 550-1105mm

| Arm size (2)

| | 876-1472mm

| Width between posts

| | 2830mm

| Lifting capacity

| | 4.5T |

|